Top Steel Pipes Manufacturers in India – Quality, Innovation & Industrial Growth

India has emerged as a global center for high-quality steel pipe manufacturing, supplying durable and versatile pipes for construction, engineering, manufacturing, and infrastructure development. With advanced technology, modern production units, and adherence to international quality standards, steel pipes manufacturers in India have built a strong reputation across the world. Whether it is stainless steel, MS, ERW, seamless, or galvanized pipes, Indian manufacturers provide products that meet the growing industrial requirements with precision and reliability.

What Are Steel Pipes?

Steel pipes are cylindrical, hollow tubes made from various grades of steel, designed to transport liquids, gases, and solid materials. They are also used in structural applications such as building frameworks, furniture, railings, and machinery.

Common types include:

-

Stainless Steel Pipes

-

Mild Steel (MS) Pipes

-

ERW Pipes

-

Seamless Pipes

-

Galvanized Iron (GI) Pipes

-

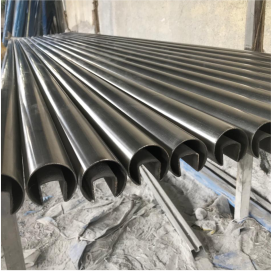

Slotted & Decorative Pipes

These pipes are known for strength, corrosion resistance, and long service life, making them suitable for both industrial and commercial use.

Why India Is a Global Leader in Steel Pipe Manufacturing?

Several factors make India a trusted market for steel pipes:

1. Advanced Manufacturing Technology

Indian manufacturers use cutting-edge machinery for welding, rolling, shaping, polishing, coating, and testing.

2. High-Quality Raw Materials

The steel used is certified and tested, ensuring durability and strength.

3. International Standards Compliance

Products follow ISO, ASTM, ISI and other global specifications.

4. Competitive Pricing

India offers premium-quality pipes at economical rates compared to global markets.

5. Huge Production Capacity

Large manufacturing setups help meet both local and export demand efficiently.

How Steel Pipes Are Manufactured?

The production process involves multiple stages:

1. Raw Material Selection

High-grade steel coils or billets are selected based on the pipe type.

2. Forming and Welding

ERW or Seamless technology is used to shape and weld the steel into pipe form.

3. Heat Treatment & Annealing

Pipes undergo heat processes to improve strength and durability.

4. Sizing & Shaping

Pipes are shaped into round, square, rectangular, or special shapes like oval or slotted.

5. Surface Finishing

Processes include polishing, powder coating, galvanizing, and PVD coating.

6. Testing & Quality Inspection

Every pipe is tested for:

-

Thickness accuracy

-

Corrosion resistance

-

Pressure handling capacity

-

Welding strength

-

Dimensional accuracy

Benefits of Using Steel Pipes

✓ High Strength & Durability

Steel pipes maintain structural integrity even under high pressure and temperature.

✓ Corrosion-Resistant

Stainless steel and GI pipes offer long-lasting resistance to rust and chemicals.

✓ Versatile Applications

Used in plumbing, construction, furniture, agriculture, oil & gas, and industrial machinery.

✓ Cost-Effective Solution

Long service life reduces maintenance and replacement costs.

✓ Eco-Friendly

Steel is recyclable, making it a sustainable construction material.

Conclusion

Steel pipe manufacturers in India play a critical role in the growth of infrastructure, industry, and engineering sectors. With superior production technology, strict quality control, and a wide range of product offerings, India is now recognized as a reliable global supplier. Whether you need pipes for construction, water supply, fabrication, automotive parts, or industrial applications, Indian-made steel pipes deliver unmatched strength, quality, and value.

FAQs

1. What types of steel pipes are commonly manufactured in India?

India produces stainless steel, MS, seamless, ERW, GI, slotted, and decorative steel pipes.

2. Are Indian steel pipes good for export?

Yes, Indian pipes meet international standards and are exported worldwide.

3. What industries use steel pipes?

Construction, plumbing, oil & gas, agriculture, automotive, and fabrication industries.

4. Are steel pipes durable?

Steel pipes are highly durable and offer long service life due to their strength and corrosion resistance.

5. Do manufacturers offer customized sizes?

Yes, most manufacturers provide custom lengths, thicknesses, shapes, and finishes.

.png)

Comments

Post a Comment